Contact Us 630-543-4565

Engineering Excellence in Vibratory Finishing

UltraMatic

Built to run. Built to last.

Trusted Leader Since 1959

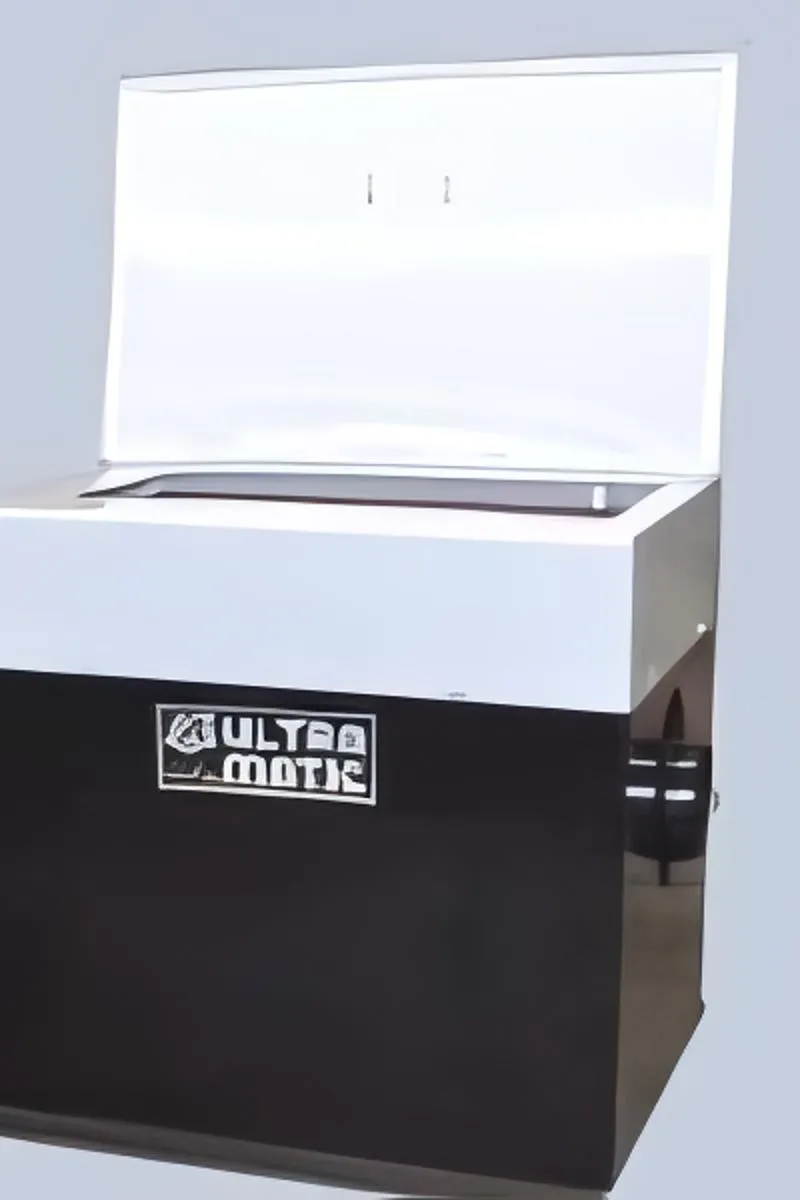

Vibratory Tubs

Ultramatic's Vibratory Tub Finishing Machines are designed for high-performance deburring, polishing, and surface conditioning of metal and composite parts. Ideal for parts that are long, delicate, or require careful spacing, vibratory tubs allow for complete control over media flow and part movement.

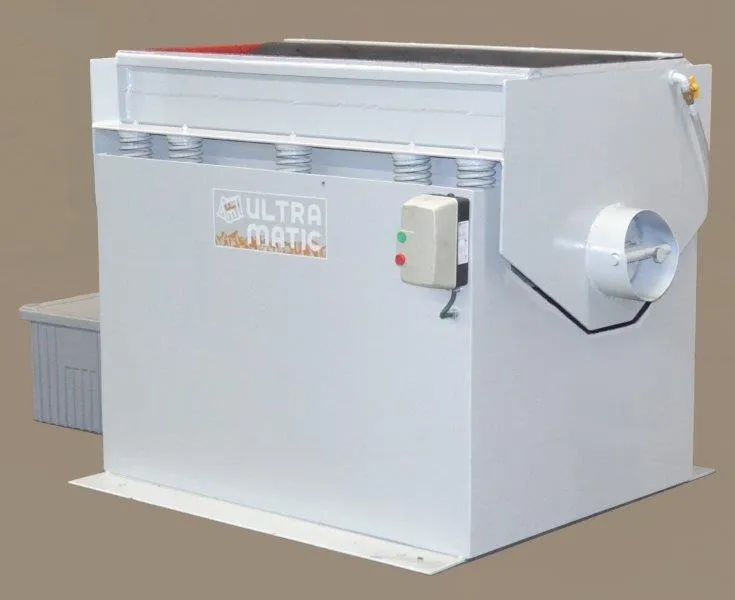

Vibratory Bowls

Ultramatic’s Vibratory Bowl Finishing Machines offer powerful, consistent performance in a space-saving design. Perfect for deburring, polishing, descaling, and burnishing, these bowls are ideal for small-to-medium-sized parts that require precise, repeatable results.

Media/Abrasives

UM Abrasives manufactures vibratory tumbling media in various ceramic compositions and shapes, along with Plastic Media. Our line of vibratory tumbling compounds is environmentally friendly and comes in 5 and 55 Gallon containers. We offer vibratory tumbling equipment in all sizes and shapes. Shipping is available from our Texas and Illinois locations.

Need Help Choosing the Right Finishing Solution?

Companies That Trust UltraMatic

Top Sellers

P6 SE Tub

DETAILS

Ultramatic Equipment Model P6 SE featuring direct drive , sound enclosure , VSD (variable speed drive and more.)

SB-2V Bowl

DETAILS

Ultramatic Model SB-2V Vibratory Deburring and Finishing Bowl Machine with parts separation.

VB 3.5 Bowl

DETAILS

Ultramatic Model VB3.5VT Vibratory Deburring and Finishing Bowl Machine.

About Our Family-Owned Business

Welcome to UltraMatic Equipment Company, where tradition meets innovation in surface finishing technology. Since our inception in 1959, we have been at the forefront of developing advanced vibratory finishing machines and media. Our commitment to excellence is deeply rooted in every product we craft, ensuring unparalleled performance in deburring, polishing, and surface preparation.

At UltraMatic, we understand that the quality of finish can make or break a product. That's why our American-made equipment and media are designed to deliver precision and efficiency, tailored to meet the diverse needs of industries ranging from aerospace to automotive, medical to military. Our expertise is not just in manufacturing top-of-the-line equipment but also in providing solutions that enhance productivity and quality for our clients.

Founded in 1959 by Achilles (Red) Ferrara, we take pride in our legacy of innovation, continuously evolving to incorporate the latest technologies and environmental standards. Our dedication goes beyond equipment; we are committed to building lasting relationships with our clients, offering expert consultation and responsive support. Choose UltraMatic Equipment Company - where excellence in surface finishing is not just a promise, but a tradition.

FAQS

What are vibratory bowl finishing machines best used for?

Vibratory bowl finishing machines are best used for deburring, polishing, descaling, and surface conditioning of small to medium-sized parts. Their circular design allows for consistent part movement and media coverage, making them ideal for high-volume batch processing. These machines are commonly used in metalworking, aerospace, automotive, medical device manufacturing, and firearms industries — anywhere precision and uniform finishes are required. They’re particularly effective for: Removing sharp edges or burrs after machining Smoothing surfaces prior to plating or painting Burnishing for a polished, mirror-like finish Cleaning components without damaging delicate features With optional media separators and variable speed controls, vibratory bowls offer both performance and flexibility — making them a reliable choice for mass finishing applications.

What machine should I use for my vibratory finishing?

The right vibratory finishing machine depends on the size, shape, material, and volume of the parts you're processing. In general: Use a vibratory bowl machine for small to medium-sized parts, especially when processing in batches. Bowls are compact, efficient, and ideal for uniform edge finishing, polishing, or descaling. Use a vibratory tub machine for larger, longer, or delicate parts that require separation during finishing. Tubs offer more control over part movement and media flow, which is critical for complex shapes or fragile materials. Other considerations include: Type of finishing required (deburring, polishing, burnishing, etc.) Part quantity and production volume Wet vs. dry processing Media compatibility and separation needs. Best option is to speak with one of our specialists.

What’s the difference between vibratory bowls and tubs?

The main difference between vibratory bowls and vibratory tubs lies in their design, part capacity, and ideal use cases:

Vibratory Bowl Machines

Feature a circular, toroidal (donut-shaped) chamber

Best for small to medium-sized parts processed in bulk

Offer consistent part-media contact and high throughput

Often include automatic separation systems

Compact footprint — ideal for high-volume shops with limited space

Vibratory Tub Machines

Have a long, rectangular chamber

Designed for long, large, or delicate parts that can’t tumble against each other

Allow for part separation using divider plates

Provide more control over media flow and part orientation

Commonly used in aerospace, medical, and custom manufacturing

In short: Choose a bowl when you're processing many small parts efficiently Choose a tub when working with larger or more delicate parts that need extra space or care

Still unsure? We’ll help you choose the right finishing system for your specific parts, materials, and production goals.

What media is used in vibratory finishing, polishing and deburring?

Vibratory finishing uses specialized media — small shapes made from abrasive or non-abrasive materials — to smooth, polish, clean, or deburr parts. The media flows around the parts inside the machine, creating consistent surface contact for uniform finishing.

Common types of vibratory media include:

Ceramic Media - Best for aggressive deburring and cutting Ideal for hard metals like steel or iron Comes in various shapes for tight spaces

Plastic Media - Lighter, less abrasive than ceramic Ideal for softer metals (aluminum, brass) or delicate parts Great for smoothing and light deburring

Organic Media - (Corn Cob, Walnut Shell) Used in dry polishing or cleaning applications Non-abrasive — ideal for final finishing or removing light oils

The best media depends on your part material, desired finish, and application (deburring vs polishing, cutting vs cleaning, etc.). Need help choosing the right media for your process? Our experts can help you match your parts with the ideal media type, shape, and size.

Do your machines support wet or dry finishing?

Yes — Ultramatic vibratory finishing machines can support both wet and dry finishing processes, depending on your specific application and the media you use.

Wet Finishing

The most common process

Uses water and compounds with abrasive media

Helps with cooling, lubrication, and removal of debris/sludge

Ideal for deburring, descaling, and smoothing metal or plastic parts

Reduces part-on-part damage and produces cleaner surfaces

Dry Finishing

Uses organic media (like corn cob or walnut shell) without liquid

Great for polishing, light cleaning, or oil removal

Often used for delicate parts or where water use must be minimized

Typically slower than wet finishing but ideal for final-stage processing

Our machines are fully compatible with both methods — and we can help you choose the right media, compound, and cycle time based on your material and finish goals.

Can I run multiple parts/materials at the same time?

Yes, you can run multiple parts at once in a Ultramatic vibratory finishing machine — that’s one of its key advantages. However, whether you can mix different materials or part types depends on a few important factors:

OK to Combine When:

Parts are made from the same or similar material (e.g., aluminum with aluminum)

They are of similar hardness and shape

There is no risk of part-on-part damage

You're using a general-purpose media that works across all items

Be Cautious When:

Parts have sharper edges or fragile features

One part could damage another (e.g., mixing soft brass with hardened steel) Parts have significantly different weights or sizes, which can lead to uneven processing

In critical applications or when parts must be kept separated, vibratory tub machines with divider plates are a better choice. These allow you to process different parts or materials in the same cycle — safely and efficiently.

Not sure if your parts can be run together? Our team can review your materials and recommend the safest, most efficient setup.

What size machine do I need for my production volume?

The right vibratory finishing machine size depends on your part size, quantity, material, and desired cycle time. As a general rule of thumb:

Small Machines (1–3 cu. ft.)

Ideal for low-volume production, prototypes, or job shops

Great for small parts or short finishing cycles

Compact footprint — perfect for tight workspaces

Medium Machines (3–10 cu. ft.)

Designed for moderate daily throughput

Handle a mix of part sizes and production runs

Popular for metalworking, fabrication, and small-batch manufacturing

Large Machines (10+ cu. ft.)

Best for high-volume production lines or large/heavy parts

Common in automotive, aerospace, and industrial manufacturing

Can process hundreds or thousands of parts per cycle

Keep in mind:

Bowl machines are typically used for bulk, high-throughput processing

Tub machines are often sized based on individual part length and whether dividers are used

If you're unsure, we can help you calculate the best machine size based on your daily part volume, part geometry, and desired finish quality.

Photo Gallery

Testimonials

James M.

★ ★ ★ ★ ★

"We’ve used Ultramatic machines for over 20 years — they just don’t quit. Minimal maintenance, consistent results, and solid support when we need it."

Operations Manager, Aerospace Finishing Facility

Ronald J.

★ ★ ★ ★ ★

"We cut our finishing time in half and got a better surface finish across the board. The machine paid for itself within months."

Production Lead, Medical Device Manufacturer

Scott C.

★ ★ ★ ★ ★

"I wasn’t sure what machine we needed. Nick walked me through every step and helped us get the perfect setup for our parts."

Fabrication Shop Owner, Midwest

Get In Touch

630-543-4565

Address:

848 S. Westgate St.

Addison IL 60101

Email:

[email protected]

Assistance Hours :

Mon – Thurs 9:00am-4pm

Contact Us for Pricing and Availability

© Copyright 2025. Ultramatic Equipment Company . All Rights Reserved.